Bespoke creations made of fibrous plaster

In the finishing sector, fibrous plaster presents many advantages. This mixture of plaster and plant fibre provides guaranteed stability, but not just that. It is also appreciated for its acoustic and fire-stopping properties.

In addition to these beneficial technical aspects, its aesthetics are also outstanding. The strengths of fibrous plaster in creating bespoke pieces include its immaculate white colour, its ability to mimic other materials and its malleability.

An overview of the steps our ornamental plasterers follow for fibrous plaster creations

Fibrous plaster, an age-old material

Fibrous plaster, an age-old material

Before the arrival of fibrous plaster as we know it today, it all began with stucco. That material was already used in Egypt to build the pyramids, as well as in Ancient Greece. The history of fibrous plaster continued in 1850, after the French Revolution. At that time, this solid and inexpensive material made it possible to reconstruct buildings that had been destroyed.

Ornamental plasterers at workshops vs on site

Ornamental plasterers at workshops vs on site

This was when the profession of ornamental plasterer made its appearance. These plasterers are specialists in both manufacturing and installing decorative architectural elements. There is however a distinction between plasterers employed in workshops and those working on site. Both are equally essential, but their functions are different.

Operational divisions at Rouveure Marquez

Operational divisions at Rouveure Marquez

Thanks to our seasoned expertise, Maison Rouveure Marquez specializes in delivering high-end services. We can install contemporary or ornamental fibrous plaster, acoustic ceilings and suspended ceilings.

Pre-production preparation

Pre-production preparation

Before a piece can be produced, the architect draws up plans for the project site, and it’s vital to adhere to the client’s wishes. Fibrous plaster can be used to make unique, bespoke pieces, thanks in particular to the creation of custom moulds.

The design office staff are the first to consider the constraints that apply to a given project. It’s important to plan each detail so as to ensure that the finished product meets the client’s and the architect’s expectations. All constraints must be considered in advance, from the size of the room to the precise details of the creation to the time until the deadline and more. The plasterers at the Maison Rouveure Marquez workshop are also attentive to any special requests and to the constraints that apply to the production of each piece.

Bespoke production at the workshop

Bespoke production at the workshop

Preparation of tools and materials

Some pieces require the creation of templates made of zinc or wood. The ornamental plasterers then prepare the materials at the right density. The proportions are implemented directly by our teams at the workshop. Rouveure Marquez works with plaster and fibrous plaster but also Vieujot plaster for pieces to be installed outdoors.

Bases, supports, templates and moulds are items that may be needed for the manual creation step carried out by our plasterers. With special tools in hand, they can then begin producing the piece.

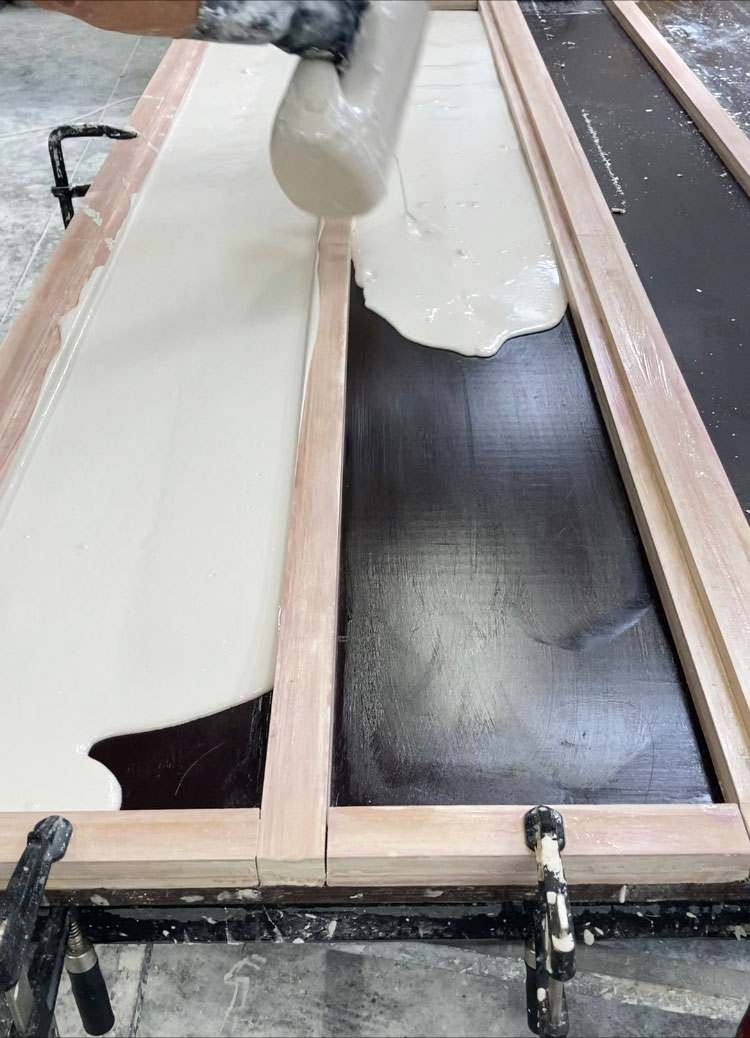

Plaster casting, drag casting, stamping and more

To produce cornices with special mouldings, our teams drag cast fibrous plaster. This entails pouring the material into a pre-made mould. To maintain all the piece’s ornamentation and/or an even thickness, our ornamental plasterers use a custom-made template to run the fibrous plaster.

One important step is solidifying the creation by means of fibreglass interlayers that provide for durability and longevity.

Many production methods can be used when working with fibrous plaster. The type of piece being made and the installation constraints are factors that need to be considered when it comes to choosing between those methods.

Plaster casting, drag casting, stamping, striating and wadding are just some of the steps that our ornamental plasterers have mastered for the creation of unique pieces that bring the imaginations of architects to life.

Mould release and drying

Once the piece has been removed from the mould, it is moved to the drying room before being collected by the plasterers who will install it on site.

On-site installation

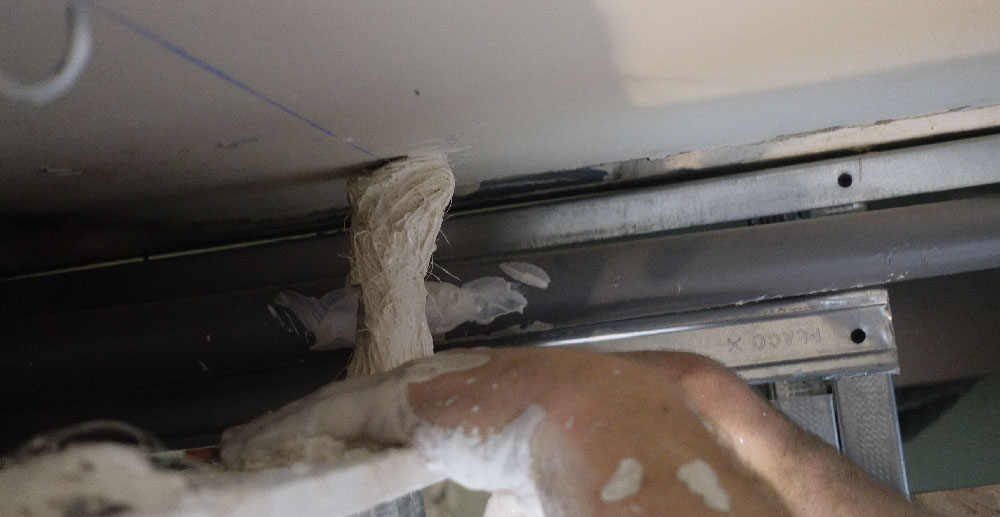

The ornamental plasterers at Maison Rouveure Marquez install each piece on site once it is nice and dry.

Specific know-how is essential to a good installation. Each install process is tailored to the site and the piece being put in place. On certain supports – like ceilings for example – the creations are bonded together with moulding plaster and plant fibre (wadding). In certain cases – such as for cornices – the fibrous plaster is glued directly to the wall and the ceiling.

From workshop to install site

From workshop to install site

Examples of past projects

More information

To read also

Discover our reproduction of pediments made of Vieujot plaster at Château de la Brigandière. Here, fibrous plaster is put to work preserving architectural heritage.

A look at the Pâtisserie Iafrati project in the heart of Vichy. A new storefront made of Vieujot plaster by our ornamental plasterers…