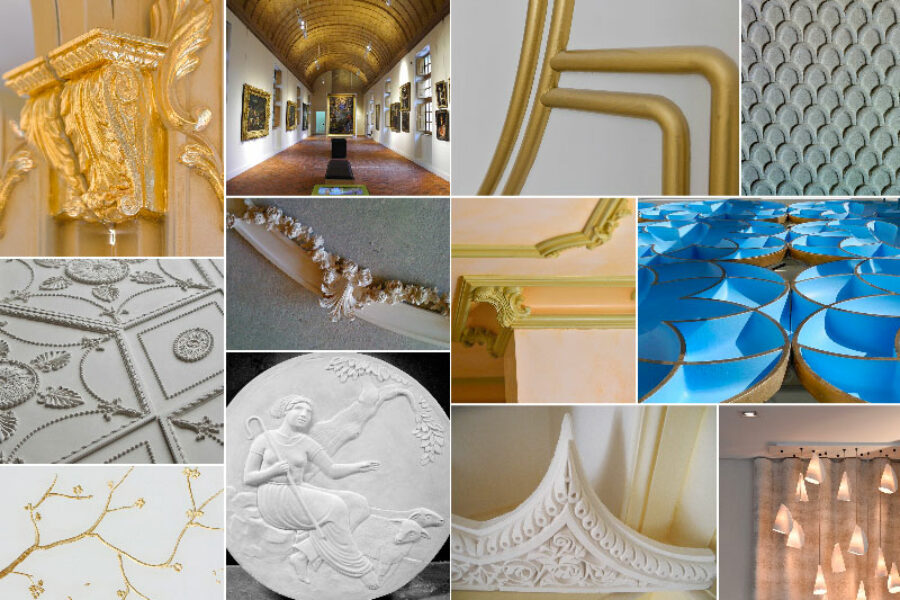

Different types of mouldings

Fibrous plaster is a supple material made of plaster of Paris and plant fibres. To give fibrous plaster the desired shape, the material is applied to moulds made of different compositions.

Ornamental plasterers use different types of moulds for their creations in fibrous plaster. Different moulds are used for classic fibrous plaster and contemporary fibrous plaster. The choice of mould is mainly determined by the complexity of the details and the size of the piece.

Characteristics and uses

With this type of mould, you can make almost anything (cornices, mouldings, roses, smooth columns, vaulting, curved ceilings, etc.)

However, these moulds are fairly fragile and are only utilized for small series.

They are often “temporary” moulds intended for use on a single project.

They are reserved for large series of pieces of limited dimensions, most often cornices.

By definition, these moulds are supple and need to be stiffened by means of a plaster or resin shell, for example, in order to prevent any deformation while casting the mould. Ornamental plasterers use them for small or large series of cornices, mouldings, roses and statuary.

The fibrous plaster pieces are then made directly on the plexiglass sheets.

Read also

Discover our fibrous plaster fireplaces for interior design. Fireplaces are real architectural pieces, adding an air of cachet and elegance to any room…

A look back at our fibrous plaster projects in 2023: luxury interior spaces for boutiques, shops and private homes, as well as international honours

From one generation to the next, ornamental plasterers have updated their know-how in order to adapt to different decorative styles, whilst retaining the skills of yesteryear.

How is fibrous plaster – a material hailed for its adaptability into a wide variety of shapes and forms – worked for use in interior architecture?

three glimpses of projects for the hospitality sector Our fibrous plaster creations made for hospitality projects led by nationally and internationally renowned architects!

Applying ancestral know-how, our ornamental plasterers follow specific steps to make fibrous plaster creations.

More information

Our teams are ready to hear all about your plans for bespoke creations for your shops, hotels, office space, restaurants and public places.